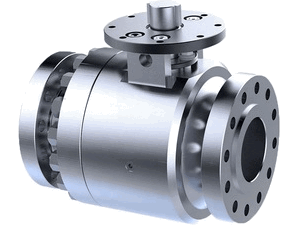

FCT Floating Ball Valve

FCT Floating Ball Valve – Compact and Efficient Shut-Off

FCT floating ball valves feature a ball suspended between two soft seats, which uses upstream pressure to press the ball tightly against the downstream seat for sealing. Their simple construction, compact size, and tight shut-off capabilities make them ideal for low- and medium-pressure applications across a variety of industries.

They are commonly used in chemical plants, utility systems, HVAC, and general-purpose pipelines where reliability, ease of maintenance, and quick actuation are key.

Technical Specifications

Design Standards: API 6D, ASME B16.34, ISO 17292

Size Range: ½” to 12” (DN15 to DN300)

Pressure Ratings: ANSI 150 to 600, PN 10 to 100

Body Types: Two-piece, Three-piece

Materials: Carbon Steel, Stainless Steel, Alloy 20, Bronze

Seat Options: PTFE, RPTFE, Devlon, Nylon (soft seated)

End Connections: Flanged, Screwed, Socket Weld, Butt Weld

Temperature Range: -20°C to +200°C

Leakage Class: ANSI Class VI / ISO 5208

Fire Safe: Optional (API 607 compliant)

Mounting Pad: ISO 5211

Key Features

Floating ball design with automatic seat sealing

Compact and lightweight body for space-constrained installations

Soft-seated tight shut-off for gas, liquid, and chemical services

Low torque operation with manual or actuated control

Quick inline maintenance with reduced downtime

Optional anti-static and blowout-proof stem

Applications

Chemical and petrochemical pipelines

Water and utility services

HVAC and building automation

General process isolation

Gas and liquid distribution systems

Food and beverage processing (with clean service versions)