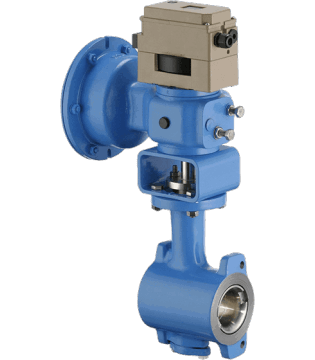

FCT Eccentric Rotary Plug Control Valves

FCT Eccentric Rotary Plug Control Valve – Robust Control for Severe Service

FCT eccentric rotary plug control valves are built for demanding process applications requiring tight shut-off, low wear, and precise throttling. Featuring an offset plug design and rotary motion, these valves combine the benefits of globe-type control with the torque efficiency of quarter-turn valves. Ideal for slurry, gas, steam, and corrosive fluids.

Technical Specifications

Valve Size: 1” to 24” (DN25 to DN600)

Pressure Ratings: ANSI 150 to 600, PN 10 to 100

End Connections: Flanged, Wafer, Lug, Welded

Body Materials: Carbon Steel, Stainless Steel, Alloy 20, Duplex, Monel

Trim Design: Eccentric offset plug with contoured control surface

Seat Options: Metal-to-metal, soft-seated, replaceable seat ring

Flow Characteristics: Linear or Modified Equal Percentage

Leakage Class: ANSI/FCI Class IV to VI

Temperature Range: -50°C to +450°C

Trim & Control Features

Offset plug design ensures low seat wear and long life

Stable control even under variable or high-pressure conditions

Low torque operation allows for smaller actuators

Compact rotary motion with precise modulating performance

Suitable for dirty, abrasive, or high-viscosity media

Actuation & Accessories

Actuator Types: Pneumatic Rotary, Electric, Hydraulic

Control Options: Direct or Reverse Acting

Accessories:

Smart or Electro-Pneumatic Positioners

Solenoid Valves, Airsets, Volume Boosters

Limit Switches, Handwheel Overrides

Applications

Slurry and abrasive fluid control

Steam and condensate regulation

High-pressure gas modulation

Refining and chemical dosing

Power plant severe service loops

Corrosive or erosive media lines