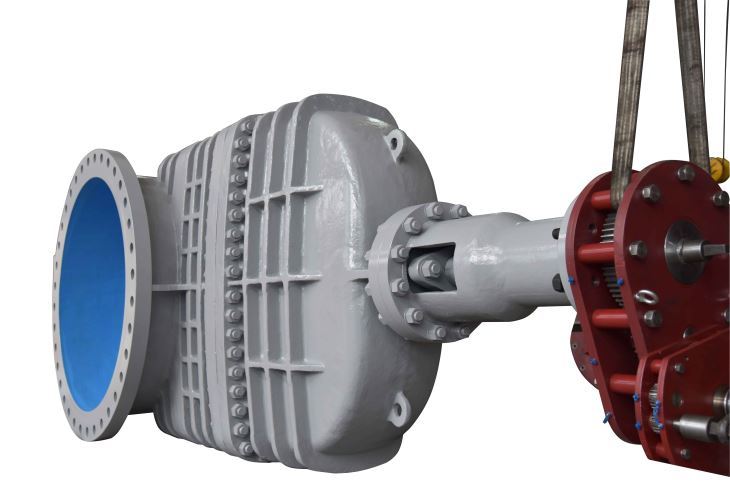

FCT Non Rising Stem Gate Valve

FCT Non-Rising Stem Gate Valve – Full Isolation in Tight Spaces

FCT non-rising stem gate valves use a fixed stem that rotates to lift or lower the gate inside the valve body, making them suitable for installations where vertical space is restricted. Unlike rising stem valves, these require no overhead clearance and are easier to install in vaults, chambers, and underground lines.

The valve design provides full bore flow and tight shut-off, minimizing pressure loss and ensuring efficient fluid control. With durable construction and a corrosion-resistant stem, these valves offer long-term performance with minimal maintenance.

Technical Specifications

Size Range: 2” to 48” (DN50 to DN1200)

Pressure Ratings: PN 10 to PN 40 / ANSI 150 to 600

Body Material: Ductile Iron, Carbon Steel, Stainless Steel

Stem Type: Fixed Non-Rising, Threaded

Seat Options: Resilient Seated (EPDM, NBR), Metal-to-Metal

End Connections: Flanged, Grooved, Socket Weld, Mechanical Joint

Operation: Manual, Gearbox, Electric Actuator

Temperature Range: -10°C to +120°C

Design Standards: AWWA C515, EN 1074, API 600 (as applicable)

Key Features

Non-rising stem design for space-saving installations

Full bore passage reduces pressure loss

Low torque operation with smooth gate movement

Corrosion-resistant stem with sealed bonnet design

Suitable for water, oil, gas, and general utility systems

Optional ISO 5210 pad for actuator mounting

Applications

Underground water and gas pipelines

Valve chambers and vaults with height limitations

Firefighting networks and hydrant lines

Industrial systems with buried or compact layouts

Wastewater and irrigation distribution

Power plants and tank farm utility lines