Cavitation in Control Valves

Cavitation is a damaging phenomenon that can occur inside a control valve when liquid flows at high velocity and pressure drops rapidly.

What Causes Cavitation?

- High-pressure drop across the valve causes the fluid pressure to fall below its vapor pressure.

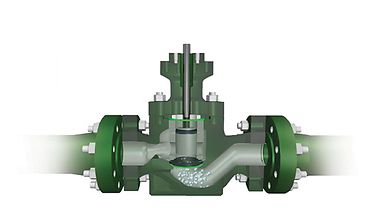

- This leads to the formation of vapor bubbles inside the fluid stream — often just downstream of the valve plug or orifice.

- As pressure recovers further downstream, these vapor bubbles collapse violently, releasing energy that hits metal surfaces.

Why Cavitation Is Dangerous

- Erodes the valve trim and body

- Causes vibration and noise

- Reduces valve lifespan

- Leads to system inefficiency and failure

How to Prevent Cavitation

- Use multi-stage pressure-reducing trim

- Select low recovery coefficient valve types (e.g., globe valves)

- Install anti-cavitation cages or special trim designs

- Limit pressure drop across the valve when possible

- Consider flash-resistant materials if cavitation is unavoidable

Real-World Tip:

Cavitation is most common in high-pressure drop liquid services — like pump discharge lines, steam condensate return, or hydrocarbon transfer.

Proper valve selection and trim design are critical in avoiding costly damage.