Control Valve Trim Characteristics: Equal Percentage, Linear, and Quick-Opening

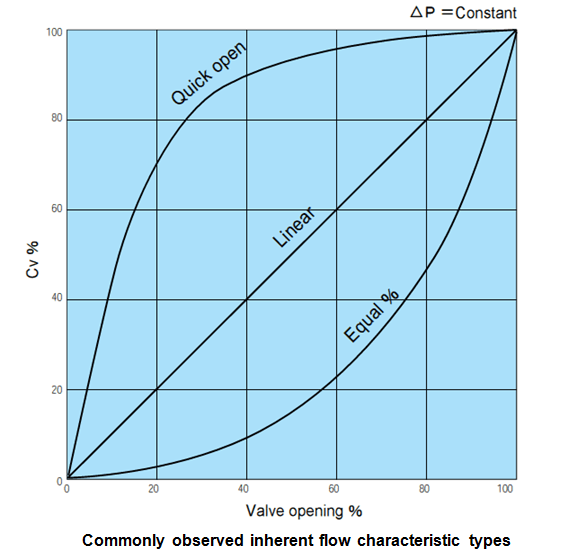

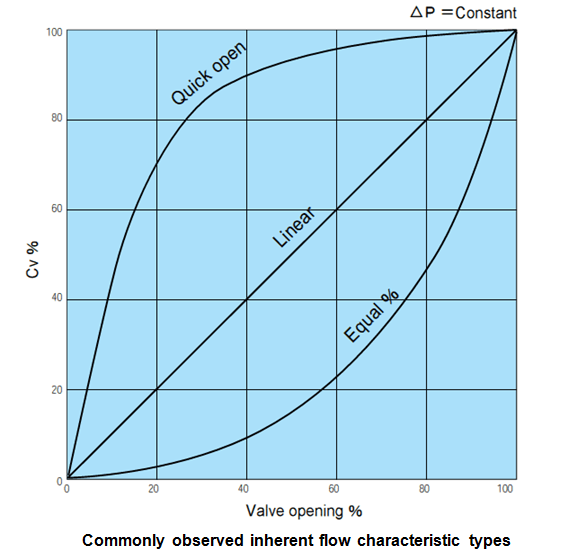

In control valves, the trim design plays a major role in defining how the valve regulates flow across its operating range. One of the most important aspects of trim design is the flow characteristic, which determines how fluid flow responds to changes in valve travel. The three primary flow characteristics used in industrial control valves are equal percentage, linear (nominal), and quick-opening (snap) — each offering a unique response profile suited to different process conditions.

Equal percentage trims are engineered so that each increment of stem travel produces a proportional percentage increase in flow. At low openings, flow changes slowly, while at higher openings, flow increases progressively faster. This makes equal percentage trims ideal for applications where the system pressure drop varies significantly, such as steam, gas, and high-pressure liquid services.

Linear trims, sometimes called nominal trims, deliver a flow change directly proportional to the valve travel. For example, 30% travel produces approximately 30% of maximum flow. This predictable behavior makes linear trims suitable for liquid service, heat exchangers, level control, and processes where system pressure remains relatively stable.

Quick-opening trims, also known as snap trims, are designed to provide a rapid increase in flow at very small openings. They achieve high flow with minimal travel, making them unsuitable for throttling but excellent for isolation, bypass, or emergency applications where fast response is critical.Choosing the right trim characteristic ensures stable control, energy efficiency, and long-term reliability. At FCT Valve, we engineer and supply control valves with all major trim characteristics to meet the performance demands of oil & gas, petrochemical, power generation, and water treatment industries.