Control valves types

Introduction

Control valves are the essential elements in any process control loop. They regulate the flow, pressure, and temperature of liquids or gases by varying the size of the flow passage according to the control signal. Choosing the right type of control valve ensures process efficiency, product quality, and operational safety.

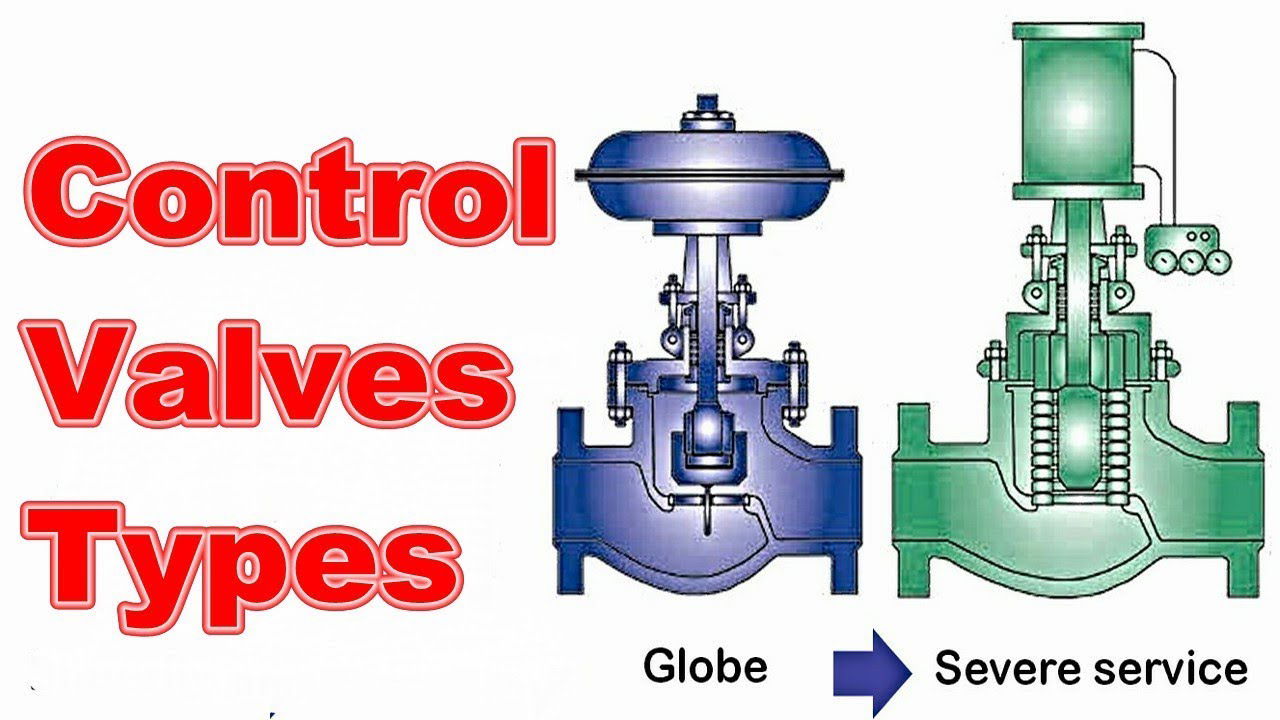

1. Globe Control Valve

The globe valve is the most common type of control valve used in industrial applications. Its linear motion and accurate throttling capability make it suitable for both high-pressure and low-flow conditions.

- Advantages: High precision, good shut-off capability.

- Applications: Steam, water, and chemical services.

2. Butterfly Control Valve

The butterfly valve is a rotary motion valve that uses a disc to regulate flow. It provides a lightweight, compact design ideal for large pipe diameters.

- Advantages: Simple structure, low cost, fast response.

- Applications: HVAC systems, water treatment, oil & gas pipelines.

3. Ball Control Valve

The ball valve offers excellent control performance for both on/off and throttling applications. Its quarter-turn movement ensures tight shut-off with minimal leakage.

- Advantages: Quick operation, minimal pressure drop, low maintenance.

- Applications: Oil, gas, petrochemical, and general industrial systems.

4. Plug Control Valve

The plug valve uses a cylindrical or conical plug with a passage through it to control flow. It is highly durable in corrosive or abrasive service.

- Advantages: Compact design, easy to maintain.

- Applications: Chemical industries, slurry services, and corrosive media.

5. Cage Type Control Valve

The cage-guided control valve (or cage type single-seat valve) uses a perforated cage for guiding the plug and controlling the flow pattern.

- Advantages: Excellent stability, low noise, suitable for high-pressure drops.

- Applications: Steam and gas control, refinery operations.

6. Diaphragm Control Valve

The diaphragm valve uses a flexible diaphragm to regulate flow, providing bubble-tight shut-off for clean and corrosive media.

- Advantages: Leak-proof design, ideal for sterile environments.

- Applications: Water treatment, pharmaceuticals, and food processing.

7. Needle Control Valve

The needle valve is used for precise flow control in small flow rate applications. Its narrow needle-like plunger allows accurate adjustments.

- Advantages: High accuracy, excellent for fine-tuning.

- Applications: Instrumentation, gas sampling systems, laboratory services.

Conclusion

Each type of control valve offers unique characteristics to meet different industrial needs. Selecting the proper valve depends on flow rate, pressure, temperature, and the nature of the fluid.

At FCT Valve, we supply a full range of control valves designed for accuracy, durability, and reliable performance in every process condition.