At FCT, we design and manufacture a wide range of on-off valves engineered for rapid and reliable shut-off control in demanding industrial environments.

Unlike control valves that regulate flow continuously, on-off valves are designed to fully open or fully close — providing immediate isolation or flow initiation when required. Our pneumatic actuated on-off valves combine mechanical strength, tight sealing, and fast actuation — making them essential for automated process systems in oil and gas, petrochemical, power generation, and water treatment industries.

What Is an On-Off Valve?

An on-off valve is a type of actuated valve that allows or stops fluid flow completely.

FCT on-off valves are typically equipped with pneumatic actuators, enabling quick response times and reliable operation under high pressure or temperature conditions. These valves are ideal for emergency shutdown, process safety, and automated switching applications where speed and precision are critical.

How On-Off Valves Work

The working principle is simple but highly efficient:

- When compressed air enters the pneumatic actuator, it drives the valve to open or close completely.

- The valve position can be controlled remotely via an automation system.

- FCT designs ensure minimal air consumption and long actuator life, reducing operating costs and maintenance downtime.

Types of On-Off Valves Manufactured by FCT

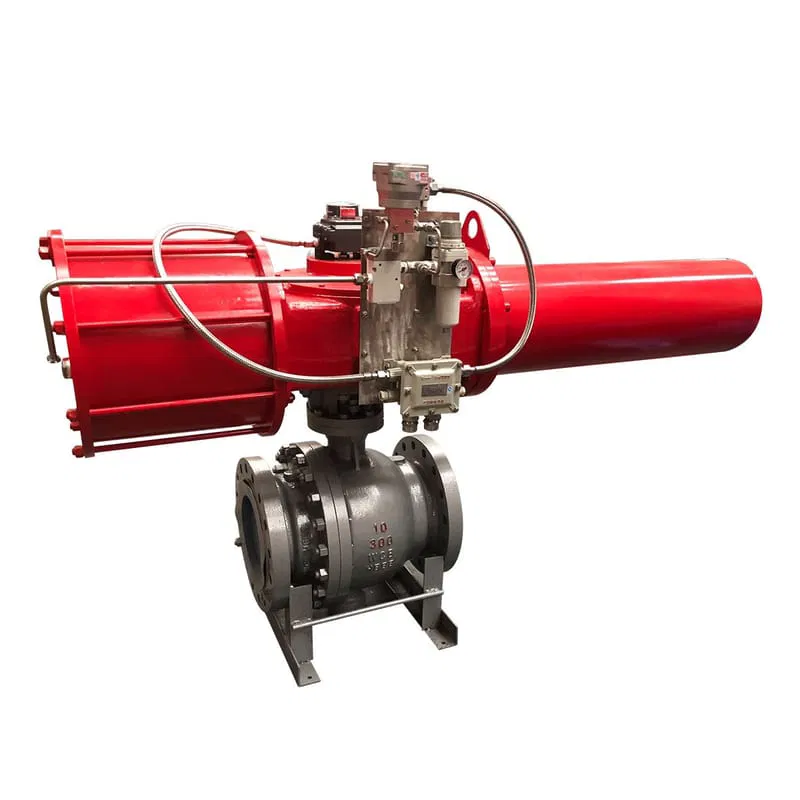

FCT manufactures and customizes a broad range of on-off valve configurations, including:- Pneumatic Ball On-Off Valves – for tight shut-off in liquid or gas service

- Butterfly On-Off Valves – ideal for large pipeline diameters and low-torque operation

- Plug On-Off Valves – suitable for high-cycle applications

- Globe On-Off Valves – for process isolation in high-pressure systems

- PTFE-Lined On-Off Valves – for corrosive and chemical media

Each valve can be fitted with solenoid valves, limit switches, and position indicators, providing full integration with plant automation systems.

Advantages of FCT On-Off Valves

- Fast Operation: Quick response through pneumatic actuation

- High Reliability: Engineered for continuous industrial service

- Tight Shut-Off: Prevents leakage and ensures process safety

- Custom Design: Available in a variety of materials and configurations

- Automation Ready: Fully compatible with control systems and smart positioners

Applications of On-Off Valves

FCT on-off valves are used in systems requiring fast flow isolation and process automation, such as:- Oil and Gas Pipelines

- Refineries and Petrochemical Plants

- Power Generation Units

- Water and Wastewater Treatment Plants

- Steam and Utility Systems

Commitment to Quality and Standards

Every FCT on-off valve is designed, assembled, and tested according to international standards such as API, ASME, EN, and ISO.

All pneumatic actuators are available in single-acting (spring return) or double-acting configurations, ensuring reliability in critical applications.

When speed, safety, and precision matter most, FCT On-Off Valves provide the ideal solution.

With durable construction, advanced pneumatic actuation, and adherence to global standards, FCT ensures seamless automation and dependable flow control in every operation.