CAST STEEL VALVES

ASTM A216 WCA, WCB, WCC (CARBON STEEL HIGH-TEMP.)

The ASTM A 216 covers 3 grades of carbon steel (WCA, WCB, and WCC), which feature slight differences in terms of chemical and mechanical properties. These grades for cast valves bodies match carbon steel pipes in grade A 53, A 106, API 5L.

ASTM A216 steel castings shall be heat treated and can be manufactured in the annealed, or normalized, or normalized and tempered conditions. The surface of steel castings shall be free of adhering elements such as sand, cracks, hot tears, and other defects.

| ASTM A216 carbon steel valves (cast), material chart | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A216 GRADE | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| WCA UNS J02502 | 0.25(1) | 0.70(1) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

| WCB UNS J03002 | 0.30(2) | 1.00(2) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

| WCC UNS J02503 | 0.25(3) | 1.20(3) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

Notes:

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% manganese above the specified maximum is allowed up to a maximum of 1.10%.

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% Mn above the specified maximum is allowed up to a maximum of 1.28%.

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% manganese above the specified maximum is allowed to a maximum of 1.40%.

ASTM A352 LCB/LCC (CARBON STEEL LOW-TEMP.)

The ASTM A352 specification covers multiple grades of low-temperature carbon steel (called LCA, LCB, LCC, LC1, LC2, LC3, LC4, LC9, CA6NM) for cast steel valves, flanges, fittings, and other pressure-containing parts.

Chemical composition of A352 cast valves Gr. LCA/LCB/LCC (valve material chart):

| GRADE | C | Si | Mn | Cr | Mo | Ni | Cu | Nb | V |

| ASTM A352 LC3 | 0.15 | 0.6 | 0.65 | 3.5 | |||||

| ASTM A352 LCA | 0.25 | 0.6 | 0.7 | 0.5 | 0.2 | 0.5 | 0.3 | 0.03 | |

| ASTM A352 LCB | 0.3 | 0.6 | 1 | 0.5 | 0.2 | 0.5 | 0.3 | 0.03 | |

| ASTM A352 LCC | 0.25 | 0.6 | 1.2 | 0.5 | 0.2 | 0.5 | 0.03 |

ASTM A351 CF8/CF8M (STAINLESS STEEL)

The ASTM A 351 specification covers austenitic steel castings for valves, flanges, fittings, and other pressure-containing parts.

The most common grades are ASTM A351 CF3, CF8 (SS304), and CF8M (SS316).

The steel shall be made by the electric furnace process with or without separate refining such as argon-oxygen decarburization.

Any ASTM A351 cast part shall receive heat treatment followed by a quench in water or rapid cooling. The steel shall conform to the chemical and mechanical requirements set by the specification.

| ASTM A351 stainless steel valves, chemical composition | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A351 GRADE | UNS | C | Mn | Si | S | P | Cr | Ni | Mo | Nb | V | N | Cu |

| CF3+CF3A | J9270 | 0.03 | 1.5 | 2.0 | 0.040 | 0.040 | 17.0-21.0 | 8.0-11.0 | 0.50 | ||||

| CF8+CF8A | J9260 | 0.08 | 1.5 | 2.0 | 0.040 | 0.040 | 18.0-21.0 | 8.0-11.0 | 0.50 | ||||

| CF3M+CF3MA | J9280 | 0.03 | 1.5 | 1.50 | 0.040 | 0.040 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | ||||

| CF8M | J9290 | 0.08 | 1.5 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | ||||

| CF3MN | J92804 | 0.03 | 1.5 | 1.50 | 0.040 | 0.040 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | 0.10-.20 | |||

| CF8C | J92710 | 0.08 | 1.5 | 2.0 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 0.50 | ( 1 ) | |||

| CF10 | J92950 | 0.04-0.10 | 1.5 | 2.0 | 0.040 | 0.040 | 18.0-21.0 | 8.0-11.0 | 0.50 | ||||

| CF10M | J92901 | 0.04-0.10 | 1.5 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | ||||

| CH8 | J9340 | 0.08 | 1.5 | 1.50 | 0.040 | 0.040 | 22.0-26.0 | 12.-15.0 | 0.50 | ||||

| CH10 | J93401 | 0.04-0.10 | 1.5 | 2.0 | 0.040 | 0.040 | 22.0-26.0 | 12.-15.0 | 0.50 | ||||

| CH20 | J93402 | 0.04-0.20 | 1.5 | 2.0 | 0.040 | 0.040 | 22.0-26.0 | 12.0-15.0 | 0.50 | ||||

| CK20 | J94202 | 0.04-0.20 | 1.5 | 1.75 | 0.040 | 0.040 | 23.0-27.0 | 19.0-22.0 | 0.50 | ||||

| HK30 | J94203 | 0.25-0.35 | 1.5 | 1.75 | 0.040 | 0.040 | 23.0-27.0 | 19.0-22.0 | 0.50 | ||||

| HK40 | J94204 | 0.35-0.45 | 1.5 | 1.75 | 0.040 | 0.040 | 23.0-27.0 | 19.0-22.0 | 0.50 | ||||

| HT30 | N08030 | 0.25-0.35 | 2.0 | 2.50 | 0.040 | 0.040 | 13.0-17.0 | 33.0-37.0 | 0.50 | ||||

| CF10MC | 0.10 | 1.50 | 1.50 | 0.040 | 0.040 | 15.0-18.0 | 13.0-16.0 | 1.7-2.25 | ( 2 ) | ||||

| CN7M | N0807 | 0.07 | 1.50 | 1.50 | 0.040 | 0.040 | 19.0-22.0 | 27.5-30.5 | 2.0-3.0 | 3.0-4.0 | |||

| CN3MN | J94651 | 0.03 | 2.0 | 1.0 | 0.010 | 0.040 | 20.0-22.0 | 23.5-25.5 | 6.0-.0 | 0.18-.26 | 0.75 | ||

| CE8MN | 0.08 | 1.0 | 1.50 | 0.040 | 0.040 | 22.5-25.5 | 8.0-11.0 | 3.0-.5 | 0.10-.30 | ||||

| CG-6MMN | J93790 | 0.06 | 4.0-6.0 | 1.0 | 0.030 | 0.040 | 20.5-23.5 | 11.5-13.5 | 1.50-3.0 | 0.10-.30 | 0.10-.30 | 0.20-.40 | |

| CG8M | J9300 | 0.08 | 1.50 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-13.0 | 3.0-4.0 | ||||

| CF10SMnN | J92972 | 0.10 | 7.0-9.0 | 3.50-.50 | 0.030 | 0.060 | 16.0-18.0 | 8.0-9.0 | 0.08-.18 | ||||

| CT15C | N08151 | 0.05-0.15 | 0.15-.50 | 0.50-.50 | 0.030 | 0.030 | 19.0-21.0 | 31.0-.0 | 0.50-.50 | ||||

| CK-3MCuN | J93254 | 0.025 | 1.20 | 1.0 | 0.010 | 0.045 | 19.5-20.5 | 17.5-19.5 | 6.0-7.0 | 0.18-.24 | 0.50-1.0 | ||

| CE20N | J92802 | 0.20 | 1.50 | 1.50 | 0.040 | 0.040 | 23.0-26.0 | 8.0-.0 | 0.50 | 0.08-.20 | |||

| CG3M | J92999 | 0.03 | 1.50 | 1.50 | 0.040 | 0.040 | 18.0-21.0 | 9.0-.0 | 3.0-4.0 | ||||

Notes:

- Grade CF8C shall have a Niobium content 8 times above the Carbon but not over 1.00%.

- Grade CF10MC shall have a Niobium content 10 times above the Carbon but not over 1.20%.

MECHANICAL PROPERTIES CAST STEEL VALVES CHART

| ASTM CAST GRADE | Tensile strength (psi) | Yield strength (psi min) | Elongation (at 2 inches) | Reduction of Area (%) | ||

|---|---|---|---|---|---|---|

| Minimum Steel Mechanical Properties | Modulus | Approximate | ||||

| ASTM A216 Grade WCB | 70,000 | 36,000 | 22 | 35 | 27.9 | 137-1 87 |

| ASTM A352 Grade LCB | 65,000 | 35,000 | 24 | 35 | 27.9 | 137-1 87 |

| ASTM A217 Grade C5 | 90,000 | 60,000 | 18 | 35 | 27.4 | 241 Max. |

| ASTM A217 Grade WC1 | 65,000 | 35,000 | 24 | 35 | 29.9 | 215 Max. |

| ASTM A217 Grade WC6 | 70,000 | 40,000 | 20 | 35 | 29.9 | 215 Max. |

| ASTM A217 Grade WC9 | 70,000 | 40,000 | 20 | 35 | 29.9 | 241 Max. |

| ASTM A352 Grade LC3 | 65,000 | 40,000 | 24 | 35 | 27.9 | 137 |

| ASTM A217 Grade C12 | 90,000 | 60,000 | 18 | 35 | 27.4 | 180-240 |

| ASTM A351 Grade CF-8 | 65,000 | 28,000 | 35 | – | 28 | 140 |

| ASTM A351 Grade CF-8M | 70,000 | 30,000 | 30 | – | 28.3 | 156-170 |

| ASTM A126 Class B | 31,000 | – | – | – | – | 160-220 |

| ASTM A126 Class C | 41,000 | – | – | – | – | 160-220 |

| ASTM A395 Type 60-45-15 | 60,000 | 45,000 | 15 | – | 23-26 | 143-207 |

| ASTM A439 Type D-2B | 58,000 | 30,000 | 7 | – | – | 148-211 |

| ASTM B62 | 30,000 | 14,000 | 20 | 17 | 13.5 | 55-65* |

| ASTM B143 Alloy 1A | 40,000 | 18,000 | 20 | 20 | 15 | 75-85* |

| ASTM B147 Alloy 8A | 65,000 | 25,000 | 20 | 20 | 15.4 | 98* |

| ASTM B148 Alloy 9C | 75,000 | 30,000 | 12 min. | 12 | 17 | 150 |

| (Weldable Grade) | 65,000 | 32,500 | 25 | – | 23 | 120-170 |

| ASTM A494 (Hastelloy B) | 72,000 | 46,000 | 6 | – | – | – |

| ASTM A494 (Hastelloy C) | 72,000 | 46,000 | 4 | – | – | – |

| Stellite No. 6 | 121,000 | 64,000 | 01.feb | – | 30.4 | – |

| ASTM B211 Alloy 20911-T3 | 44,000 | 36,000 | 15 | – | 10.2 | 95 |

| ASTM B16 1/2 Hard | 45,000 | 15,000 | 7 | 50 | 14 | – |

| ASTM B21 Alloy 464 | 60,000 | 27,000 | 22 | 55 | – | – |

| AISI 12L 14 | 79,000 | 71,000 | 16 | 52 | – | 163 |

| ASTM A108 Grade 1018 | 69,000 | 48,000 | 38 | 62 | – | 143 |

| (Suitable for ASTM A193 Grade B7 bolt material) | 135,000 | 115,000 | 22 | 63 | 29.9 | 255 |

| ASTM A276 Type 302 | 85,000 | 35,000 | 60 | 70 | 28 | 150 |

| ASTM A276 Type 304 | 85,000 | 35,000 | 60 | 70 | – | 149 |

| ASTM A276 Type 316 | 80,000 | 30,000 | 60 | 70 | 28 | 149 |

| ASTM A276 Type 316L | 81,000 | 34,000 | 55 | – | – | 146 |

| ASTM A276 Type 410 | 75,000 | 40,000 | 35 | 70 | 29 | 155 |

| ASTM A461 Grade 630 | 135,000 | 105,000 | 16 | 50 | 29 | 275-345 |

| Alloy K500 (K Monel) | 100,000 | 70,000 | 35 | – | 26 | 175-260 |

| ASTM B335 (Hastelloy B) | 100,000 | 46,000 | 30 | – | – | – |

| ASTM B336 (Hastelloy C) | 100,000 | 46,000 | 20 | – | – | – |

RECOMMENDED SERVICE (CAST VALVE MATERIALS)

The table shows the most common materials for cast valves and their recommended service:

| MATERIAL GROUP | MATERIAL GRADE | RECOMMENDED SERVICE |

|---|---|---|

| High-temperature Carbon Steel | ASTM A216 Grade WCB | Non-corrosive fluids as water, oil, and gases at temperatures range -20°F (-30°C) and +800°F (+425°C) |

| Low-temperature Carbon Steel | ASTM A352 Grade LCB | Low temperature to -50°F (-46°C). Use excluded above +650°F (+340°C). |

| Low-temperature Carbon Steel | ASTM A352 Grade LC1 | Low temperature to -75°F (-59°C). Use excluded above +650°F (+340°C). |

| Low-temperature Carbon Steel | ASTM A352 Grade LC2 | Low temperature to -100°F (-73°C). Use excluded above +650°F (+340°C). |

| 3.1/2% Nickel Steel | ASTM A352 Grade LC3 | Low temperature to -150°F (-101°C). Use excluded above +650°F (+340°C). |

| 1.1/4% Chrome 1/2% Moly Steel | ASTM A217 Grade WC6 | Non-corrosive fluids as water, oil, and gases at temperatures range -20°F (-30°C) and +1100°F (+593°C). |

| 2.1/4% Chrome | ASTM A217 Grade C9 | Non-corrosive fluids as water, oil and gases at temperatures range -20°F (-30°C) and +1100°F (+593°C). |

| 5% Chrome 1/2% Moly | ASTM A217 Grade C5 | Mild corrosive or erosive applications and non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C). |

| 9%Chrome 1% Moly | ASTM A217 Grade C12 | Mild corrosive or erosive applications and non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C). |

| 12% Chrome Steel | ASTM A487 Grade CA6NM | Corrosive application at temperatures between -20°F (-30°C) and +900°F (+482°C). |

| 12% Chrome | ASTM A217 Grade CA15 | Corrosive application at temperatures up to +1300°F (+704°C) |

| Stainless steel 316 | ASTM A351 Grade CF8M | Corrosive or either extremely low or high-temperature non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater. |

| Stainless steel 347 | ASTM 351 Grade CF8C | Mainly for high temperature, corrosive applications between -450°F (-268°C) and +1200°F (+649°C). Above +1000°F (+540°C) specify carbon content of 0.04% or greater. |

| Stainless steel 304 | ASTM A351 Grade CF8 | Corrosive or extremely high temperatures non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater. |

| Stainless steel 304L | ASTM A351 Grade CF3 | Corrosive or non-corrosive services to +800F (+425°C). |

| Stainless steel 316L | ASTM A351 Grade CF3M | Corrosive or non-corrosive services to +800F (+425°C). |

| Alloy-20 | ASTM A351 Grade CN7M | Good resistance to hot sulfuric acid to +800F (+425°C). |

| Monel | ASTM 743 Grade M3-35-1 | Weldable grade. Good resistance to corrosion by all common organic acids and salt water. Also highly resistant to most alkaline solutions to +750°F (+400°C). |

| Hastelloy B | ASTM A743 Grade N-12M | Well suited for handling hydrofluoric acid at all concentrations and temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C). |

| Hastelloy C | ASTM A743 Grade CW-12M | Good resistance to span oxidation conditions. Good properties at high temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C). |

| Inconel | ASTM A743 Grade CY-40 | Very good for high-temperature service. Good resistance to spangly corrosive media and atmosphere to +800°F (+425°C). |

| Bronze | ASTM B62 | Water, oil or gas: up to 400°F. Excellent for brine and seawater service. |

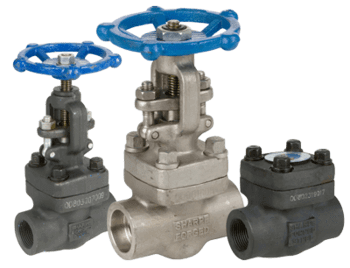

FORGED STEEL VALVES

Forged bodies are common for small diameter valves (generally, below 2 inches) or for high-pressure valves that require extreme robustness and solidity. Forged bodies are less prone to leakages than cast valve body materials.

The ASTM A105, ASTM A350, and ASTM A182 specifications cover materials for carbon, low-alloy, and stainless steel forged valves.

The chemical and mechanical properties of the ASTM carbon, alloy, stainless material (A105, A350, A182) are illustrated in this article.

RECOMMENDED SERVICE

The table shows the most common materials for forged valves and their respective recommended service:

Forged Material Grade

| ASTM Grade | Material Name | Recommended Service |

| 304 | 19%Chrome 9%Nickel | Applications at temperatures up to +1000°F (+538°C). |

| 316 | 19%Chrome, 10%Nickel 2%Moly | Applications at temperatures up to +1000°F (+538°C). |

| 321 | 18%Chrome, 10%Nickel with Titanium | Applications at temperatures up to +800°F (+427°C). |

| 347 | 18%Chrome, 10%Nickel with Columbium | 347 has good intergranular-corrosion resistance and is resistant to atmospheric conditions between temperatures of +800°F(+427°C) and +1650°F(+899°C). |

| 400 | Monel | This nickel alloy has good corrosion resistance, good weldability and, high strength. Great mechanical properties at subzero temperatures up to +1000°F (+538°C). |

| 410 | 13%Chrome 1/2%Moly | 410 is the basic martensitic stainless. It has good impact strength, corrosion and scaling resistance up to +1200°F (+649°C). |

| 420 | 13%Chrome, 1%Nickel 1/4%Moly | Full corrosion resistance only in the hardened or hardened and stress relieved conditions. The temperature should be below +800°F (+427°C). |

| 600 | Inconel | This nickel-chromium alloy has good oxidation resistance at higher temperatures to +2000°F (+1093°C) |

| 625 | Inconel | This nickel-chromium alloy has good carburization and oxidation in high-resistance at higher temperatures to +2000°F (+1093°C). |

| 825 | Incoloy | Alloy 825 has a high level of corrosion resistance in both reducing and oxidizing environments and good mechanical properties at temperatures up to +1000°F (+538°C). |

| 17-4PH | 15-1/2%Chrome 4-1/2%Nickel | Good corrosive resistance properties at temperatures up to +600°F (+316°C). |

| 304H | 18%Chrome 9%Nickel | Applications at temperatures up to +800°F (+427°C). |

| 304L | 19%Chrome, 10%Nickel Low Carbon | Applications at temperatures up to +800°F (+427°C). |

| 316H | 18%Chrome, 8%Nickel with Molybdenum | Applications at temperatures up to +800°F (+427°C). |

| 316L | 19%Chrome, 10%Nickel 2%Moly, Low Carbon | Applications at temperatures up to +800°F (+427°C). |

| 317L | 25%Chrome, 21%Nickel 3/4%Moly | 317L has superior corrosion resistance in difficult environments and can be used at temperatures between +1700°F (+927°C) to +2200°F (+1204°C). |

| 440C | 17%Chrome 3/4%Moly | This grade is used in the hard plus tempered condition. For best corrosion resistance, the tempering temperature should be below +800°F (+427°C). |

| 800H/HT | Incoloy | This nickel-chromium alloy has good carburization and oxidation in high-resistance and normally used in temperatures above +1100°F (+593°C). |

| A105N | 1/4% Max Carbon Steel | Non-corrosive applications including water, oil and, gases at temperatures between -20°F (-30°C) and +800°F (+427°C). |

| ALLOY 20 | 20%Chrome, 35%Nickel 2-1/2%Moly | Good resistance to hot sulfuric acid to +800°F (+425°C). |

| C276 | Hastelloy | This nickel-molybdenum-chromium alloy has excellent corrosion resistance in a wide range of corrosive media and corrosion resistant to ambient temperatures. |

| F11 | 1-1/4%Chrome 1/2%Moly | Non-corrosive applications including water, oil and, gases at temperatures between -20°F (-30°C) and +1100°F (+593°C). |

| F22 | 2-1/4%Chrome 1%Moly | Non-corrosive applications including water, oil and, gases at temperatures between -20°F (-30°C) and +1100°F (+593°C). |

| F5 | 5%Chrome 1/2%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| F51 | 22%Chrome, 5%Nickel 3%Moly | F51 is a super duplex stainless steel. Good Moderate to good corrosion resistance in a variety of environments. Service to +600°F (+316°C). |

| F53 | 25%Chrome, 7%Nickel 4-1/2%Moly | F53 is a super duplex stainless steel. This material has excellent corrosion resistance in a variety of environments. Service to +600°F (+316°C). |

| F55 | 25%Chrome, 7%Nickel 3-1/2%Moly | This material combines high mechanical strength and good ductility with excellent corrosion resistance in environments with temperatures up to +600°F (+316°C). |

| F9 | 9%Chrome 1%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| F91 | 9%Chrome 1%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| K500 | Monel | This nickel alloy has good corrosion resistance. Monel K500 has great mechanical properties at subzero temperatures up to about +480°C. |

| LF2 | Low Temp Carbon Steel | Non-corrosive applications at temperatures from -50°F (-46°C) to +800°F (+427°C). |

| X-750 | Inconel | This nickel-chromium alloy has good resistance to corrosion and oxidation along with high tensile and creep-rupture properties at temperatures up to +1300°F (+700°C). |

CROSS REFERENCE CHART: ASTM CAST VS. FORGED MATERIALS

| Material Group | Forged Grade | Equivalent Cast Grade |

| Carbon Steel | A181-Gr.1 A181-Gr.2 | |

| Moderate, high temp. service | A105-Gr.1 A105-Gr.2 | A216-WCA WCB WCC |

| Cold temp. service | A350-LF1 A350-LF2 | A352-LCB, LCC |

| Carbon -1/2 Moly Alloy Steel | ||

| High Temp Service | A182-F1 | A217-WC1 |

| Cold Temp Service | A352-LC1 | |

| 1/2Cr-1/2Mo Alloy Steel | A182-F2 | |

| 1/2Cr-1/2Mo-1 Alloy Steel | A217-WC4 | |

| 3/4Cr-1 Mo-3/4NI Alloy Steel | A217-WC5 | |

| 1Cr-1/2Mo Alloy Steel | A182-F12 | |

| 1Cr-1 Mo-Vd Alloy Steel | A404-F24 | A389-C24 |

| 1-1/4Cr-1/2Mo Alloy Steel | A182-F11 | A217-WC6 |

| 1-1/4Cr-1/2Mo-Vd Alloy Steel | A389-C23 | |

| 2-1/4Cr-1/2Mo-Vd Alloy Steel | A182-F22 | A217-WC9 |

| 3Cr-1 Mo Alloy Steel | A182-F21 | |

| 5Cr-1/2Mo Alloy Steel | A182-F5 | |

| 5Cr-1/2Mo-Si Alloy Steel | A217-Gr.C5 | |

| 7Cr-1/2Mo Alloy Steel | A182-F7 | |

| 9Cr-1 Mo Alloy Steel | A182-F9 | A217-Gr.C12 |

| 13Cr Alloy Steel | A182-F6 | A351-CA15 |

| Type 304 Stainless Steel | ||

| Standard | A182-F304 | A351-Gr.CF8 CF8a |

| Low Carbon | A182-F304-L | A351-Gr.CF3 CF3a |

| High Temp Service | A182-F304-H | A351.Gr.CF10 |

| Type 309 Stainless Steel | ||

| Type 310 Stainless Steel | A182-F310 | |

| Type 316 Stainless Steel | ||

| Standard | A182-F316 | A351-Gr.CF8M |

| Low Carbon | A182-F316-L | A351-Gr.CF3M |

| High Temp Service | A182-F316-H | A351.Gr.CF10 |

| Type 317 Stainless Steel | A403-WP317 | |

| Type 321 Stainless Steel | ||

| Standard | A182-F321 | |

| High Temp Service | A182-F321-H | |

| Type 347 Stainless Steel | ||

| Standard | A182-F347 | |

| High Temp Service | A182-F347-H | A351-Gr.CF8C |

| Type 348 Stainless Steel | ||

| Standard | A182-F348 | |

| High Temp Service | A182-F348-H | |

| 20 Ni-8 Cr Alloy | A182-F10 | |

| 2 Nickel Alloy Steel | ||

| Low Temp Service | A352-LC2 |

VALVE TRIM

The trim of a valve is the collective name for all the (replaceable) parts of a valve in direct contact with the fluid (“wet parts”).

The valve trim includes, generally, the disc/plug, the stem, the cage, the seat ring, the gaskets and the packing (the trim configuration depends on the type of valve). The API 600 trim chart designates the typical combinations with a conventional number (example, Trim 8).

The API 600 designates some typical combinations of the valve trim materials with a number (API trim #1, trim #2, etc.).

The selection of the correct combination of the trim materials is one of the most important decisions to specify valves correctly.

| API TRIM # | TRIM MATERIAL | SEAT | DISC/WEDGE | BACKSEAT | STEM |

|---|---|---|---|---|---|

| 1 | 410 | 410 | 410 | 410 | 410 |

| 2 | 304 | 304 | 304 | 304 | 304 |

| 3 | F310 | 310 | 310 | 310 | 310 |

| 4 | Hard 410 | Hard 410 | 410 | 410 | 410 |

| 5 | Hardfaced | Stellite | Stellite | 410 | 410 |

| 5A | Hardfaced | Ni-Cr | Ni-Cr | 410 | 410 |

| 6 | 410 and Cu-Ni | Cu-Ni | Cu-Ni | 410 | 410 |

| 7 | 410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 |

| 8 | 410 and Hardfaced | Stellite | 410 | 410 | 410 |

| 8A | 410 and Hardfaced | Ni-Cr | 410 | 410 | 410 |

| 9 | Monel | Monel | Monel | Monel | Monel |

| 10 | 316 | 316 | 316 | 316 | 316 |

| 11 | Monel | Stellite | Monel | Monel | Monel |

| 12 | 316 and Hardfaced | Stellite | 316 | 316 | 316 |

| 13 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 |

| 14 | Alloy 20 and Hardfaced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 |

| 15 | 304 and Hardfaced | Stellite | Stellite | 304 | 304 |

| 16 | 316 and Hardfaced | Stellite | Stellite | 316 | 316 |

| 17 | 347 and Hardfaced | Stellite | Stellite | 347 | 347 |

| 18 | Alloy 20 and Hardfaced | Stellite | Stellite | Alloy 20 | Alloy 20 |

API TRIM MATERIAL SELECTION

| TRIM | RECOMMENDED SERVICE |

|---|---|

| 13% Cr, Type 410 Stainless Steel | For oil and oil vapors and general services with heat-treated seats and wedges. |

| 13% Cr, Type 410 plus Hardfacing | Universal trim for general service requiring long service life up to 1100°F (593°C).* |

| Type 316 Stainless | For liquids and gases which are corrosive to 410 Stainless Steel, up to 1000°F (537°C).* |

| Monel | For corrosive service to 842°F (450°C) such as acids, alkalies, salt solutions, etc. |

| Alloy 20 | For corrosive services such as hot acids -49°F to 608oF (-45°C to 320°C). |

| NACE | Specially treated 316 or 410 trim combined optionally with B7M Bolts and 2HM nuts to meet NACE MR-01-75 requirements. |

| Full Stellite | Full hard-faced trim, suitable for abrasive & severe services up to 1200°F (650°C).* |

* Depends upon base material grade